what is nchrp-350 test level 3 impact|nchrp report 350 requirements : specialty store Details of most concern are connections, anchor cables, cable connections, and concrete impact (such as transformer bases or weakened barrier assemblies, and physical and chemical properties of test article elements or obtained from the supplier of. Resultado da CASA. DF. GAMA. PONTE ALTA. QUARTO (TODOS) Aceita Permuta. mais filtros. 607 Casas à venda em Ponte Alta, Gama, DF. ORDENAR. .

{plog:ftitle_list}

Resultado da Beyblade Wiki is the largest online collaborative encyclopedia about the hobby and anime, Beyblade. It covers the original series, metal series, spin-off series, Burst series, X series and more. You can find information about characters, episodes, manga, games, and upcoming releases of Beyblade.

Details of most concern are connections, anchor cables, cable connections, and concrete impact (such as transformer bases or weakened barrier assemblies, and physical and chemical properties of test article elements or obtained from the supplier of.

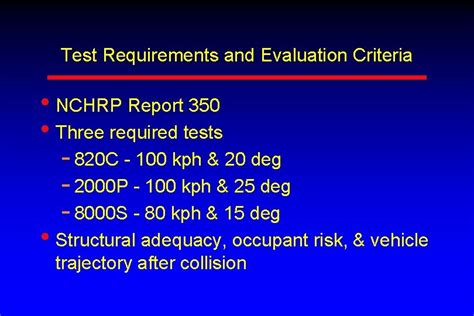

impact testing has been and will continue to be the most common method of .The purpose of the procedures is to promote the uniform testing and in .Note: The Test Levels 1 through 3 in NCHRP Report 350 represent increasing severe impact severities. In general, each impact severities is described by a combination of test vehicle( . All of the systems described in the Roadside Design Guide as meeting MASH or NCHRP Report 350, TL-3 evaluation criteria have the capability to stop compact cars and .

In general, NCHRP 350 contains two testing levels for work zone traffic control devices: the higher test level (test level 3) requires testing small cars at 20 mph and 60 mph. In the lower test .According to NCHRP Report 350, up to seven tests are recommended to evaluate gating W-beam guardrail terminals to test level three (TL-3). TL-3 is the basic test level for passenger .

An impact angle of 25 degrees is specified in NCHRP Report 350 for length-of-need and transition tests of longitudinal barriers to evaluate their strength and containment capabilities.There are up to six test levels in Report 350, depending on the feature being evaluated. All six test levels apply to longitudinal barriers, test levels 2 and 3 apply to breakaway features, and .

The purpose of the procedures is to promote the uniform testing and in-service evaluation of roadside safety features so that highway engineers may confidently compare the .

Although Report 350 defines several supplemental test vehicles as the basis for optional testing at higher performance levels, most of our current hardware has been designed and tested to .2 IMPACT CONDITIONS NCHRP Report No. 350 (1) recommends that temporary barriers be tested under the same . in order to be used on high speed facilities, temporary barriers are tested under the Test Level 3 (TL-3) criteria which involves a 2,000-kg (4,409-lb), ¾-ton pickup truck impacting the barrier at a speed of 100.0 km/hr (62.1 mph) and at anThe only component different from the FLEAT is the impact head. This greatly reduces inventory requirements. . The SKT meets NCHRP 350 Test Level 2 criteria. All of the components are the same as the Test Level 3 (100 km/hr) .

specified in the NCHRP Report 350 guidelines under Test Level 3 (TL-3), including the test vehicle, the nominal impact speed and angle, and the impact point on the device. Also, an assessment on whether the test is affected by impact speed only (A) or by a combination of impact speed and angle (B) is provided in the table.NCHRP 350 FLEAT®-MT. FLEAT-MT. How the FLEAT-MT Functions. . Depending on the severity of the impact, the vehicle may be stopped before reaching the second impact head at post #4. If the end-on impact is severe enough, the vehicle will activate the second impact head. . 37′ 6″ long for Test Level 3 design speed; Can be used with wood .test level, test level (TL) 3, in Report 350 are fundamentally the same as those as those used in Report 230 with small differences in impact speed attributed to the hard conversion to SI units of measurement. For instance, the impact speed for TL-3 is 100 km/hr or 62 mph which is slightly greater than the 60 mph nominalThe QuadGuard® II is a redirective, non-gating crash cushion that consists of an engineered steel nose and crushable, energy absorbing cartridges surrounded by a framework of steel Quad-Beam™ panels. The system is tested to NCHRP Report 350 Test Level 2 and Test Level 3. The Test Level 2 model is 25% shorter than the original QuadGuard® measuring less than 10’ (3 .

AASHTO/FHWA Joint Implementation Agreement for Manual for Assessing Safety Hardware describes the roles that AASHTO, FHWA, and agencies will play with regards to implementing safety hardware.To directly download the agreement to your computer, click here. FHWA Federal Register Notice – MASH Transition: Effective January 1, 2016, all changes to .How it Works – The impact head has 3 high strength steel cutting teeth welded on the inside. When impacted end-on, the vehicle pushes the impact head down the W-beam rail. The 3 cutting teeth in the impact head cut the rail section into 4 ribbons of steel. The Impact Head – The front impact face is square. The impact head can be recognized12-3.23B(2) Impact Attenuators Each impact attenuator must: 1. Be on the Authorized Material List for highway safety features. 2. Comply with MASH test level 3 or NCHRP 350 test level 3 up to December 31, 2026, where the posted speed limit is 50 mph or more. 3. Comply with MASH test level 2 or 3 or NCHRP 350 test level 2 or 3 up to December 31 .B. NCHRP 350 TEST LEVEL 3 TRUCK-MOUNTED IMPACT ATTENUATORS (TMAs): BRAND NAME: MANUFACTURER/SUPPLIER: Alpha 100K TMA. Energy Absorption Systems, Inc. Chicago, IL. . (NCHRP) Report 350 Test Level 3 Truck-Mounted Attenuators (TMAs), or Test Level 3 Trailer-Mounted Attenuators, are required whenever indicated in the Contract .

between MASH and NCHRP Report 350 include: Changes in Test Matrices The small car impact angle is increased from 20 to 25 degrees to match the impact angle used with light truck testing The impact speed for the single-unit truck test is increased from 80 km/h to 90 km/h to better distinguish the TL-4 test from TL-3Test Level (kJ) Velocity (km/h) Mass (kg) Angle/Position Type Test N.A. N.A. N.A. N.A. Nominal Impact Severity NCHRP350 Real Impact Severity SMA 110 PL N.A. . EN 1317 vs NCHRP-350 TL3 Impact Severity for Crash cushion Energetic Level (SMA 130) > Energetic Level (NCHRP) 0 100 200 300 400 500 600 700 800 900 1000 (kJ) Test at 130km/h

The ACZ-350® is a non-redirective, gating crash cushion that consists of an integrated steel nose and water-filled, steel reinforced plastic segments. The system is tested to NCHRP Report 350 Test Level 2 and Test Level 3. The ACZ-350® crash cushion is . TRB's National Cooperative Highway Research Program (NCHRP) Report 350: Recommended Procedures for the Safety Performance Evaluation of Highway Features presents procedures for conducting vehicle-crash tests and in-service evaluation of roadside safety features or appurtenances including (1) longitudinal barriers such as bridge rails, .NCHRP 350 Test Level 2 and Test Level 3 – NCHRP Report 350 test level 2 (TL-2) and test level (TL-3) require successful tests of a 1,800 lb. car impacting a barrier at an angle of 20 degrees and a 4,400 lb. pickup truck impacting a barrier at an angle of 25 degrees at speeds of 45 mph and 60 mph, respectively. What is NCHRP 350. Procedures are presented for conducting vehicle crash tests and in-service evaluation of roadside safety features or appurtenances. . Hence, the approach has been to normalize test .

Testing criteria and conditions for truck mounted attenuators as described in the NCHRP Report 350. The first mandatory test done in Test Level 2, Test 50, was set to, “to evaluate risks to occupants of a small car impacting the TMA.” In .

nchrp report 350 requirements

Test matrices • Vehicle type, impact speed, impact angle, impact location . Test Level 4 (TL-4) Barrier Barrier Height and Design Load Requirements. Example #2 – TL-4 Barrier NCHRP 350. MASH: . NCHRP Report 350 TL-4 36-inch tall barrier -- design impact load = 68 kips. 42-inch tall barrier -- design impact load = 80 kips .NCHRP Report 350 Compliant - Test Level - ( 2 or 3, depending on what your FHWA letter says) FHWA Accepted WZ - # # # . The decision in NCHRP Report 350 to vary impact severities by holding the vehicle and angle constant while varying the speed was based on the desire to limit the cost of testing rather than an attempt to mimic real life .

The QuadGuard® is a redirective, non-gating crash cushion that consists of crushable, energy absorbing cartridges surrounded by a framework of steel Quad-Beam™ panels. The system is tested to NCHRP Report 350 Test Level 1, Test Level 2, and Test Level 3. It can be used to shield fixed objects of 2′ to 10′-6″ wide (610 mm to 3,200 mm) while using less than 22′ in .The NCHRP 2023 Annual Report presents detailed information on NCHRP's achievements in 2023. It also provides a concise list of research published in 2023 and a list of all active projects, projects completed in 2023, and projects that were approved in .The only component different from the SKT is the impact head. This greatly reduces inventory requirements. When impacted end-on, the kinetic energy is able to be absorbed. . The FLEAT meets NCHRP 350 Test Level 2 criteria. All of the components are the same as the Test Level 3 (100 km/hr) design. The length is simply reduced. Test Level 2 .

Section 3.2.1 in the text. CHAPTER ONE A .1.1 Vehicle crash tests are complex experiments that are not easily replicated because of difficulties in controlling critical test conditions such as speed, angle, and condition of test vehicle and the sometimes random and unstable behavior of dynamic crush and fracture mechanisms.

NCHRP 350, Test Level 3, and an acceptance letter issued by the FHWA. Portable vertical panel assemblies with an auxiliary device mounted on it shall not be used unless they have been tested and approved under NCHRP 350, Test Level 3. - Portable Sign Supports - Tripod Type Tripod portable sign supports shall not be used. - Self-erecting TypeNCHRP 350 MASH PRODUCT NAME TEST LEVEL PRODUCT NAME TEST LEVEL Lindsay Transportation Solutions UNIVERSAL TAU-II ® 2 & 3 TAU-M 3 (Barrier Systems, Inc.) UNIVERSAL TAU-II-R ® 2 & 3 . Note: For Impact Attenuator Severe Use Narrow: NCHRP 350 products are allowed on lettings prior to January 1, 2019.NCHRP 350 MASH; Small car test vehicle: 820C vehicle (1,800 lbs.) 1100C vehicle (2,420 lbs.) Small car impact angle: 20° 25° Light truck test vehicle: 2000P (4,400 lbs.) 2270P (5,000 lbs.) Gating terminals and crash cushion impact angle: 15° 5° - 15° Variable message signs and arrow board trailers: No mention: Added to TMA crash test matrixThe TRB National Cooperative Highway Research Program's NCHRP -Only Document 326: Design Guidelines for Test Level 3 through Test Level 5 Roadside Barrier Systems Placed on Mechanically Stabilized Earth Retaining Walls is dedicated to developing guidelines for barrier-moment slab systems placed over MSE walls to resist vehicular impact loads .

rockwell hardness tester brinell tensile strength

webEntrar . Wisu RH 2024

what is nchrp-350 test level 3 impact|nchrp report 350 requirements